Linking machine data to IT

Networking machines and devices with other systems.

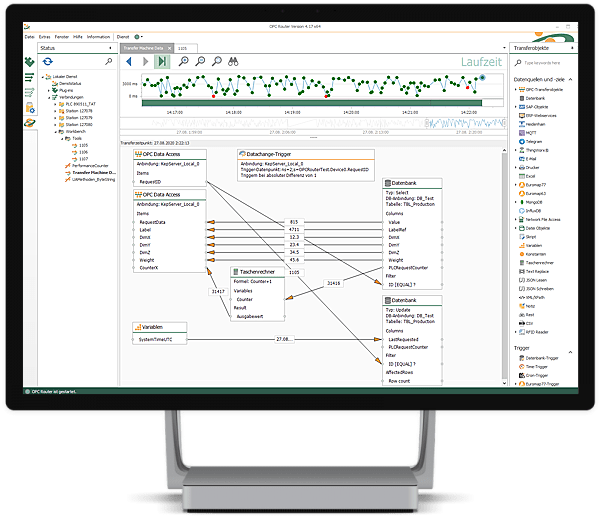

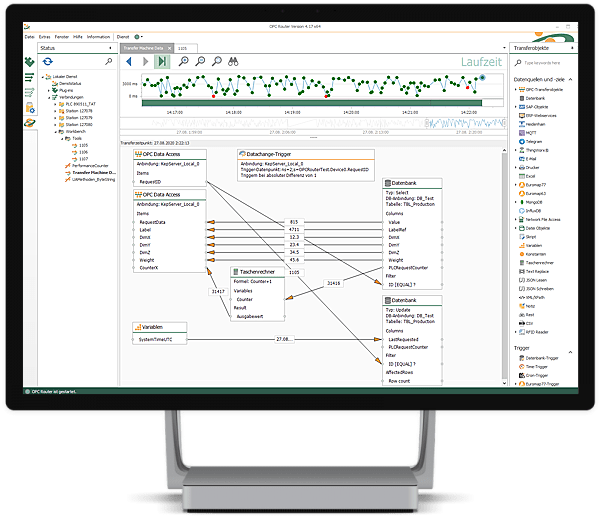

Via drag & drop, reliably and securely: The OPC router makes it possible.

Linking machine data to IT

Networking machines and devices with other systems.

Via drag & drop, reliably and securely: The OPC router makes it possible.

Provide machine data company-wide

As middleware, the OPC Router connects a wide variety of systems with each other. The graphical interface makes it easy to connect different machines and devices, ERP systems, databases or cloud environments. Data transfer from a machine is automated and reliable. The OPC Router links your systems with each other and creates an automated data exchange in your production.

How machine data acquisition works

Machine data collection refers to the process of collecting, monitoring and analyzing data from machines in real time to optimize the performance, efficiency and maintenance needs of machines and production facilities. With the OPC Router, this data can be made available company-wide for other systems and software solutions or for the image of a machine. Watch our video to see how OPC UA is used to transfer machine data to a database.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSatisfaction is the best reference

How to realize your REST connection

The OPC Router realizes the communication to the different systems by means of extensions, the so-called plug-ins. These plug-ins offer a multitude of freely combinable connection options in order to optimally adapt to your project. You can choose between the OPC Router REST plug-in, SAP plug-in, SQL Server plug-in and many other plug-ins and connection options.