OPC UA Client Plug-in

OPC UA – One of the most important protocols for your Industry 4.0 project

The first version of the OPC standard was published in 1994 and has since developed and spread rapidly. OPC provides a general standard for accessing automation components.

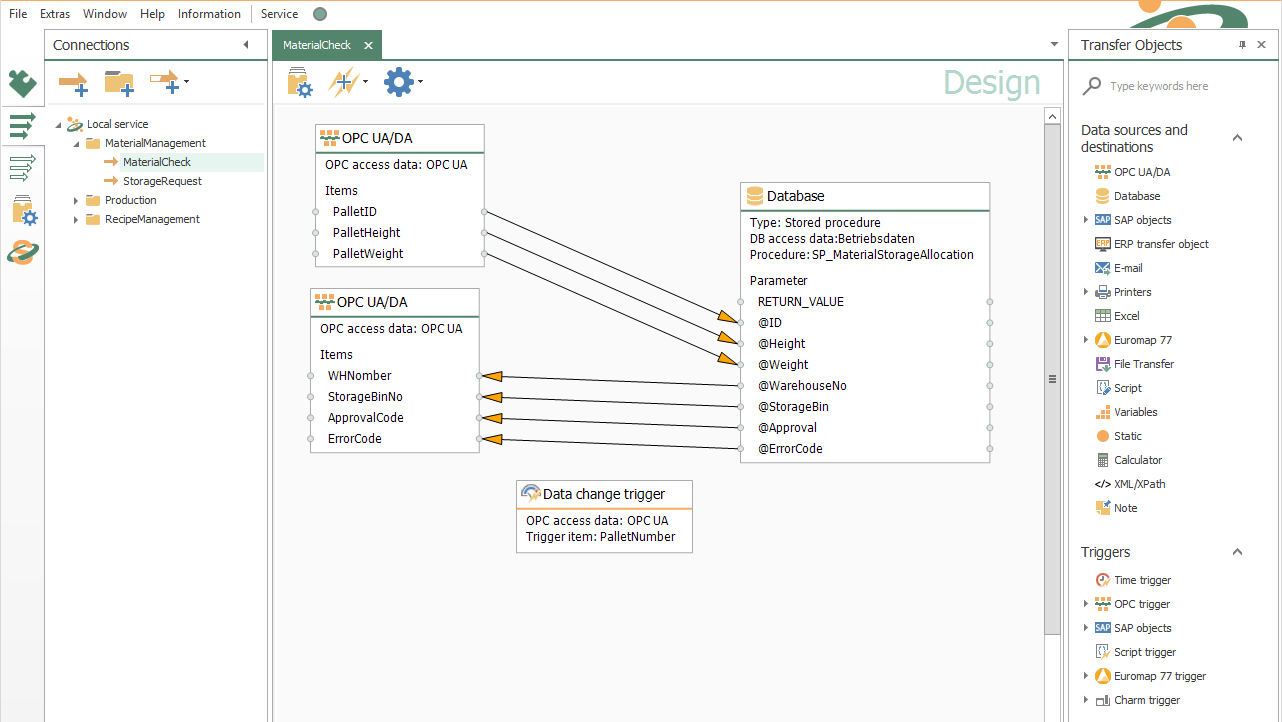

The OPC Router is an OPC UA/DA client which can read and write data from OPC Servers and couple this data to various systems (see screenshot). The OPC Servers are supplied either by the manufacturer of the automation component itself or by third-party manufacturers. With the new OPC UA (Unified Architecture) standard, it is also possible for the first time for automation devices to realise an implementation of the standard on their own, non-Windows-based platforms and thus serve as OPC UA Servers themselves (e.g., WAGO PFC-200 or Siemens S7-1500).

You can find a dedicated video with the caption “OPC Router as UA/DA client and OPC UA server” on this topic in our tutorial stream.

These and other customers rely on the OPC Router

That’s how easy it is.

OPC UA connection via drag & drop

The connection of your systems via OPC UA is quite easy and intuitive with OPC Router using drag & drop. In the screenshot we show you an example of a connection of the OPC Router as an OPC UA Client. The OPC UA/DA client functionality loads items from an OPC Server. These are transferred to an SQL Server (via Microsoft SQL Plug-in). The return values are then written back to the OPC Server and transferred to the controller.

Bringing Industry 4.0 to life with OPC UA

- Achieving more with coupled systems:

OPC ensures that thousands of devices can be addressed via a similar standard. Alone, each device would be a black box on its own without a proprietary connection to the outside world. Via OPC data exchange the data of the devices are available for the OPC Router and thus for all systems connected to it. - Industry 4.0 with OPC UA:

The networking of production has always been the core task of OPC. This makes OPC and especially OPC UA one of the most important protocols for implementing Industry 4.0. OPC provides the OPC clients with the data from each device at the right time and format, integrating it into the Industry 4.0 infrastructure. The OPC Router distributes the data as a gateway to the correct receivers, making Industry 4.0 alive. - About the OPC Router:

With the OPC Router as a OPC UA Gateway, you can realize the data exchange of your systems graphically. The OPC Plug-in works as an OPC UA Client.

OPC UA Client Plug-in application examples

Read OPC UA data from the PLC and write it to a database

PLCs have the task of controlling complex machine sequences and processes in automation. However, it is becoming increasingly common for decisions based on data from other systems to be made as part of the process. For example, products are produced individually according to customer requirements. The customer-specific parameters are stored in databases. The PLC can trigger a transfer of these special production parameters via the coupling with the OPC Router. The OPC Router reads the corresponding selection criteria from the PLC via OPC UA (e.g. order number), loads the data from the database and writes them via OPC UA to the PLC. The standard “OPC” allows the OPC Router to do this with any controller type and other OPC compatible devices.

Connect OPC data sources in local networks via edge computing

Industry 4.0 depends on networking. At the field level, the OPC protocol has long established itself as the leading protocol for data exchange. More devices can provide their data directly via OPC UA. In addition, OPC servers with many driver implementations, e.g. Kepware OPC Server with over 150 drivers, ensure that the majority of automation devices can be accessed via OPC UA. The OPC Router with its OPC UA client Plug-in can be used as an edge computing unit in which it connects the available OPC data sources in the local network, preprocesses and buffers data (via SQL database). The buffered data can be secured, for example, with the store & forward function. The OPC Router then transfers the data to higher-level systems (e.g. SAP) or via MQTT to the cloud. This is, of course, bidirectional, so that data from the cloud can also be sent to the devices and controllers via this way.

Receive confirmations and error messages from the shopfloor via OPC UA

The OPC Message Trigger object of the OPC Router reduces the probability of failure and can prevent production stops. When communicating with a machine the OPC Router returns an acknowledgement of receipt to the machine by means of the trigger object. When a pallet is completed, the OPC Router receives a message about this. With a so-called handshake the OPC Router confirms the completion and the PLC can automatically continue with its next job. If an error occurs during processing by the OPC Router, it sends an error message back to the PLC. This can, for example, trigger a deliberate production stop before damage to the product or machine occurs.

Video tutorial: Easy transfer of OPC Data into CSV Format

This video tutorial shows how easy it is to read process values out of an OPC UA server and save them into a CSV file. The process values are read on data change and create a new record set into an existing csv file (or creates a new one, if one already exists). Just connect OPC UA data points, CSV document and create corresponding CSV file simply via drag & drop.

Connecting Systems with the OPC Router OPC UA Client Plug-in

Transfer-Objects

The transfer object of the OPC UA Client Plug-in allows access to the data points of the OPC Server.

Data Points

The OPC standard defines the structure and organization of data points. Each data point has a unique name. As an OPC client, the OPC server provides the current value, the associated time and the quality of the value (device connected, no connection, etc.).

The desired data points are selected via browsing. These are available in the transfer object of the graphical configuration and can be connected to other fields during the transfer

Trigger

The OPC UA Client Plug-in includes several triggers.

DataChange Trigger

The DataChange Trigger is configured for an OPC data point and triggers the transfer when the data point changes.

Limit Trigger

The limit value Trigger monitors a data point for compliance with limits. It can be checked for exceeding or falling short. A hysteresis can also be set.

Bit trigger

Handshakes are often implemented for data transfers. The bit trigger is the simplest variant here. The OPC Router checks whether a bit requests a transfer. Once transferred, the bit is optionally reset or another bit is set as response. The success of the transfer can be transferred to another data point.

Message Trigger

The message trigger is the further development of the bit trigger in the form of telegram data exchange. Here not a bit is checked, but a counter is checked for a value change. In response, the number that triggered the transfer is written back after the transfer.

The reliability and traceability of this exchange is significantly higher.

Browsing

The OPC UA Client Plug-in can browse the data points of the OPC Server.

Data Point Hierarchy

The OPC Standard defines the possible ways to read data points. The standard is the hierarchical structure in form of a data point tree. The OPC Router reads all data points as a tree and displays them to the user. In this form, even large datapoints are easily accessible. Each data point is identified via the unique path and is taken over including type information.