middleware for Industry 4.0

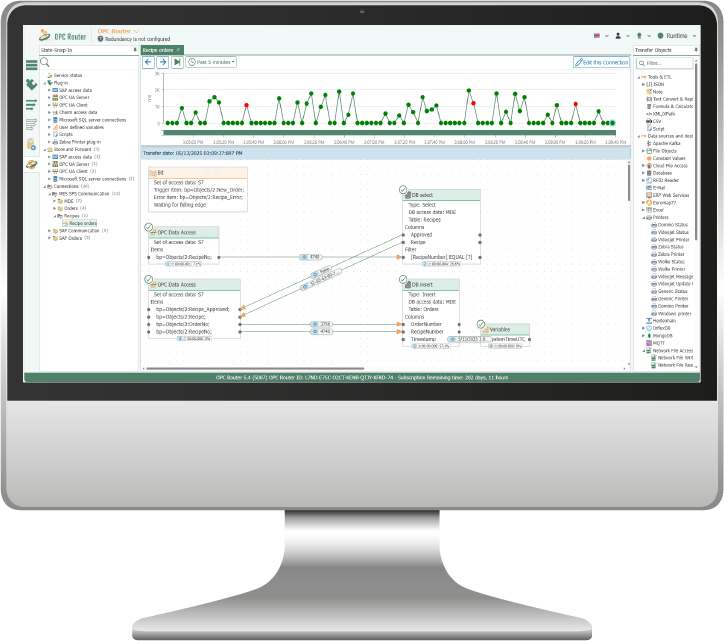

How the OPC Router works

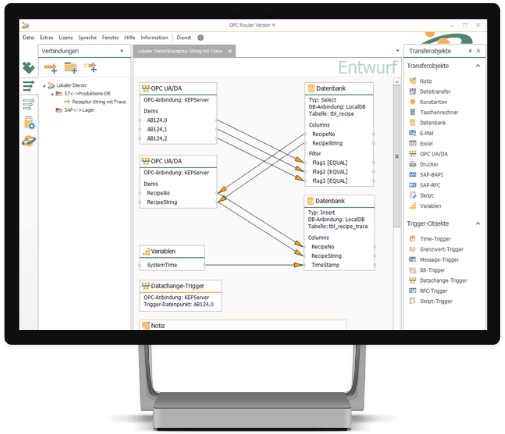

The OPC Router works like a universal translator for your systems. It enables communication between all systems and protocols and can be easily integrated into existing automation and production environments. With the right Plug-ins, you can connect different automation systems with each other via drag & drop and build your Industry 4.0 structure. In our video, we show you how quick and easy it is to get started with the OPC Router and what the most important operating elements are:

Replace outdated communication processes

As a central communication platform, the OPC Router offers automated data exchange by integrating all systems and stand-alone solutions – from sensors to the cloud. It enables complete integration of PLC, DCS, SCADA, MES, SQL servers, label printers, email servers and ERP systems.

By recording your process data, you have a continuous overview of your production. The possible applications are virtually unlimited and can be implemented by you. The OPC Router can be used simply by drag & drop – no programming skills are required.

Wi With the OPC Router you get:

- Standard interfaces for data exchange

- State-of-the-art middleware for IoT and Industry 4.0 projects

- The connection of all industry-relevant systems via powerful modular Plug-ins

- A perfect basis for your production optimization through complete transparency of your data

- A user-friendly user interface for creating connections via drag & drop

Contact us if you have any questions about the OPC Router. We are happy to help you.

These and other customers rely on the OPC Router

OPC UA – the communication standard

in Industry 4.0

What is OPC UA?

OPC UA is a platform-independent way to communicate between different devices. It is used in all automation levels and enables the connection between a wide range of systems. OPC UA is therefore treated as one of the most important IoT / Industry 4.0 protocols. All details can be found in our article: “What is OPC UA?“. The OPC Router acts as OPC Client software for OPC DA and OPC UA:

OPC to SQL – Data exchange

with SQL databases

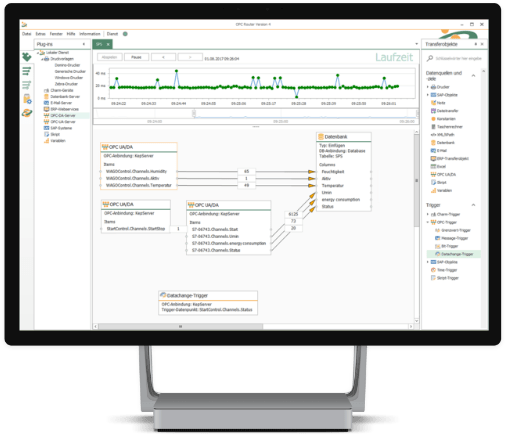

In the various production levels, databases are an important source and target for data. Production processes have to be provided with order information, recipes or machine data. Large amounts of data are generated and stored in the process. These are all aspects of the IoT/IIoT (Internet of Things/Industrial Internet of Things) and Industry 4.0.

The OPC Router is a software-based middleware that connects databases and different sources and thus drives the idea of IoT/IIoT and Industry 4.0.

The ease of implementation and administration maximises remote data access while keeping operating costs low.

Let your systems talk to each other

Here you will find further information on the various connection options with the OPC Router plug-ins. You can also test the OPC Router directly free of charge and without obligation. If you have any questions or a specific application, our team will be happy to help you.