In the ever-evolving landscape of Industry 4.0 and artificial intelligence (AI), the bridge between language models and real-world production data is critical. This article looks at the Model Context Protocol (MCP) and shows how the OPC Router can effectively act as an MCP server to enable AI-driven systems such as chat assistants to access and interact with industrial processes.

What is the Model Context Protocol (MCP)?

The Model Context Protocol (MCP) is an innovative protocol specifically designed to provide Large Language Models (LLMs) with contextual information from external systems. It enables LLMs to go beyond their original training data set and dynamically access up-to-date data and features. For language models, the benefits of an MCP server are immense: it transforms them from static knowledge bases into interactive tools that can react to changing conditions in real time and make data-driven decisions. This is particularly relevant in highly dynamic environments such as industrial production.

The OPC Router as an MCP server: Industry 4.0 for language models

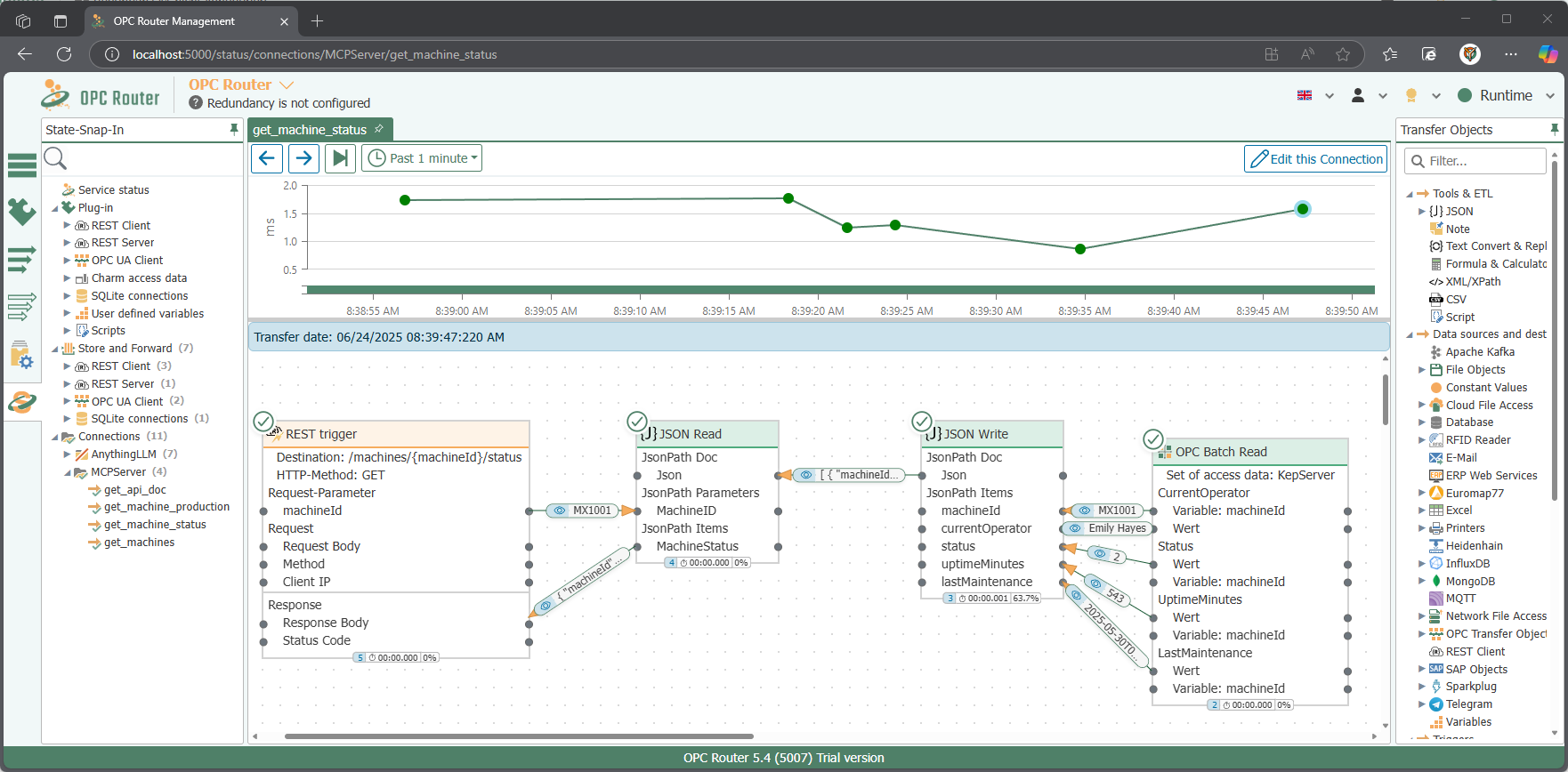

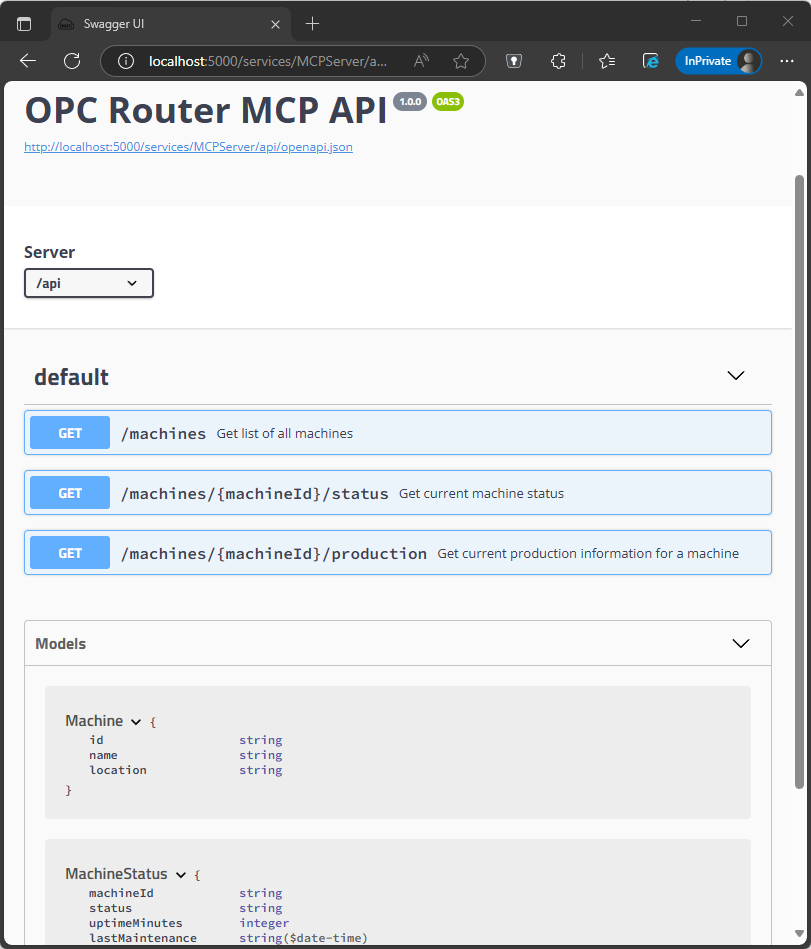

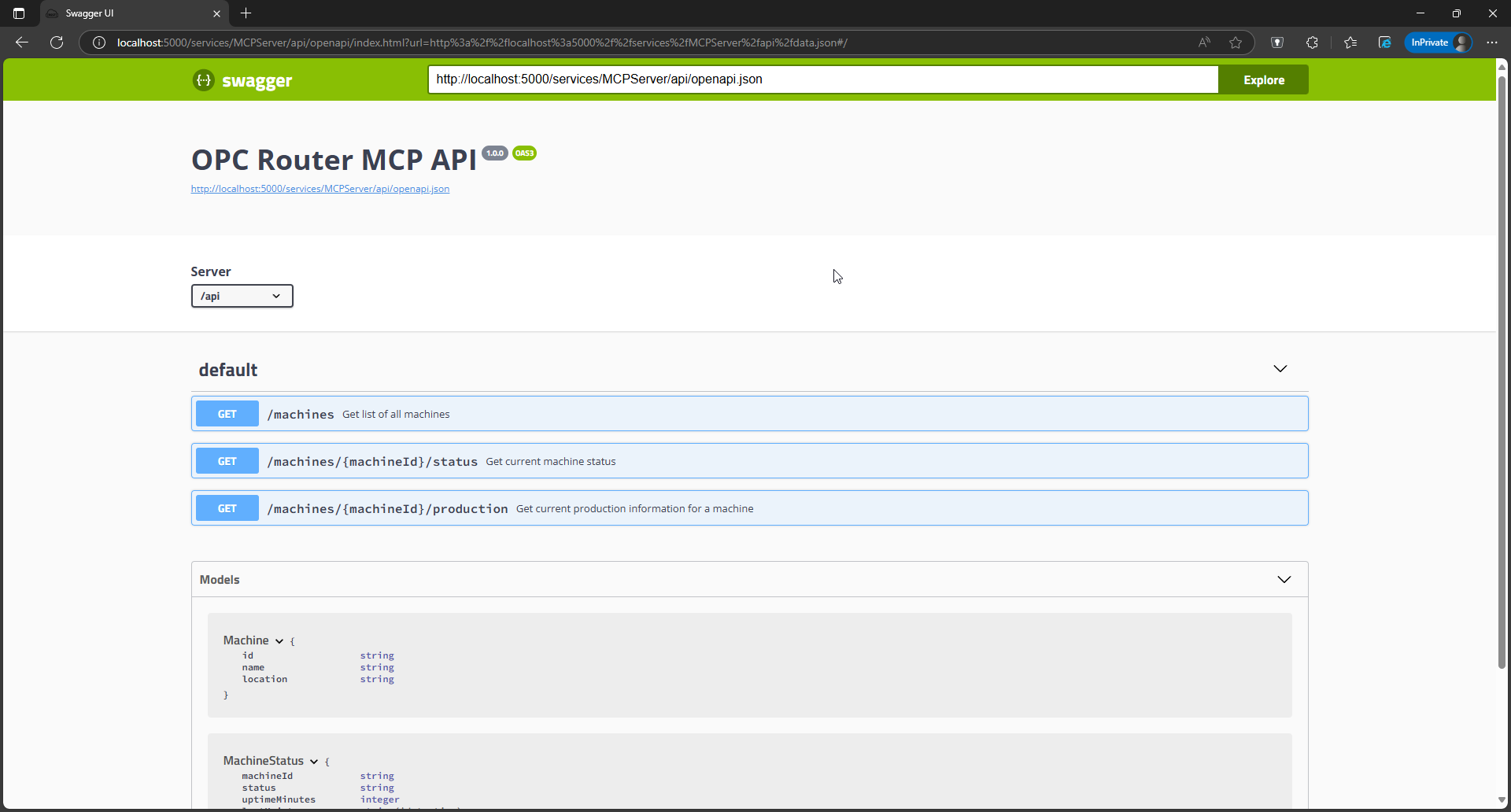

The OPC Router can act as an MCP server. It translates the complex and heterogeneous data from industry – from PLCs and sensors to MES systems – into a format that is understandable for language models.

- Integration with Claude Client: A screenshot shows the seamless integration of these functions into a Claude Client, illustrating the practical application and interaction with the language model.

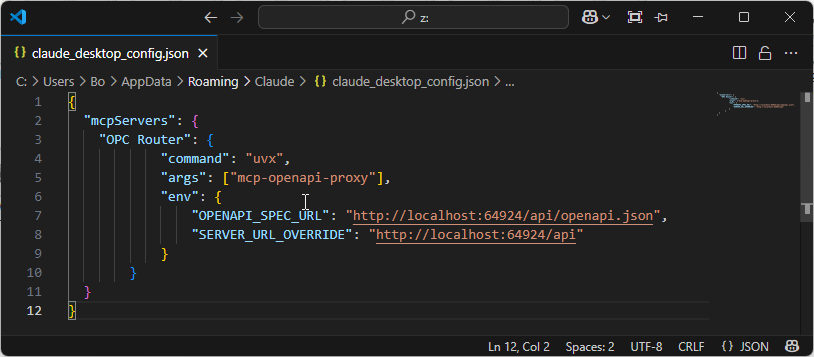

- MCP server configuration: The configuration of the OPC Router as an MCP server is surprisingly simple, as the screenshot of the MCP server configuration file shows. This facilitates quick implementation in existing systems.

- Application example in action: A short video shows the use of this setup, in which the language model is able to query specific machine statuses and react on the basis of this information.

This integration allows the OPC Router to act as an intermediary that provides a language model or chat assistant with the “eyes and ears” of Industry 4.0. The voice model can then answer questions such as: “Which machine is currently idle?” or “Is there a free machine for the production of X?”.

Derivations and future possibilities

The OPC Router’s ability to act as an MCP server opens up a wide range of opportunities for companies looking to take full advantage of AI in their Industry 4.0 strategy:

- Intelligent monitoring and maintenance: language models can proactively inform about anomalies or impending machine failures and make recommendations for maintenance work, based on real-time data.

- Optimized production planning: AI assistants can help dynamically adjust production schedules by reacting to current machine utilization and material availability.

- Improved decision making: Management and technicians can access complex plant data via intuitive voice interfaces and make more informed decisions.

- Automated problem solving: In conjunction with other automation tools, voice models could even independently recognize simple problems and trigger their resolution.

- Interactive operating instructions: Instead of static manuals, language models could dynamically provide instructions on machine operation based on the current state of the plant.

The combination of MCP, OPC Router and language models is a further step towards a fully integrated and intelligent factory in which data flows and decisions are made in real time. The OPC Router makes it possible for your language models not only to talk, but also to really understand what is going on in your production.

Conclusion: A powerful tool with up-and-coming potential

The integration of the OPC Router as an MCP server is not only an exciting, but also an extraordinarily powerful tool. What we have seen here goes far beyond simply querying information. The ability to enable not only read but potentially also write access via the OpenAPI interfaces opens up the prospect of controlling interventions using language models. Imagine if an AI assistant could not only query the status of a machine, but also adjust production parameters or start and stop machines based on real-time data and predefined rules. This is a decisive step towards a fully autonomous and intelligent factory.

However, it is important to emphasize that the Model Context Protocol (MCP) is still in the early stages of development. The integration possibilities are only just developing and many concepts, especially for edge coupling, are still in progress or pending. The potential is enormous, and the continued development of the MCP in conjunction with robust tools such as the OPC Router will fundamentally change the way we interact with and use industrial data. We are at the dawn of an era where language models can not only inform, but actively shape the industrial world.