Videojet Plug-in for the OPC Router

Videojet Inkjet connector

Videojet has been supplying reliable marking systems for many years. This also includes the inkjet printer product line.

The printers are used in industrial packaging systems for efficient coding and labeling of products. The smooth and reliable setup of the printer before production is important for efficient marking. Too long set-up times due to manual processes cost valuable time. Incorrect print data due to errors during manual set-up cause expensive rejects due to incorrectly labelled products.

By connecting the Videojet inkjet printers via OPC Router, automatic setup of the printers at production start is possible. Data can be obtained automatically from various source systems (SQL database, SAP, SPS via OPC, etc.) and transferred directly to the printer without loss of time and 100% valid.

The supported inkjet printers are Videojet 1860, 1580, 1550 / 1560 / 1650 / 1660, 2300, as well as 2120. In addition, the connection of the following printers is supported: Cloud m600 universal, Videojet DataFlex 6330 / 6530 / 6230, Cloud m610 touch and Videojet 9550.

You can find a detailed video on this topic, using the Windows printer as an example, under the description “connecting different printers” here in our tutorial stream.

That’s how easy it is.

Videojet connection via drag & drop

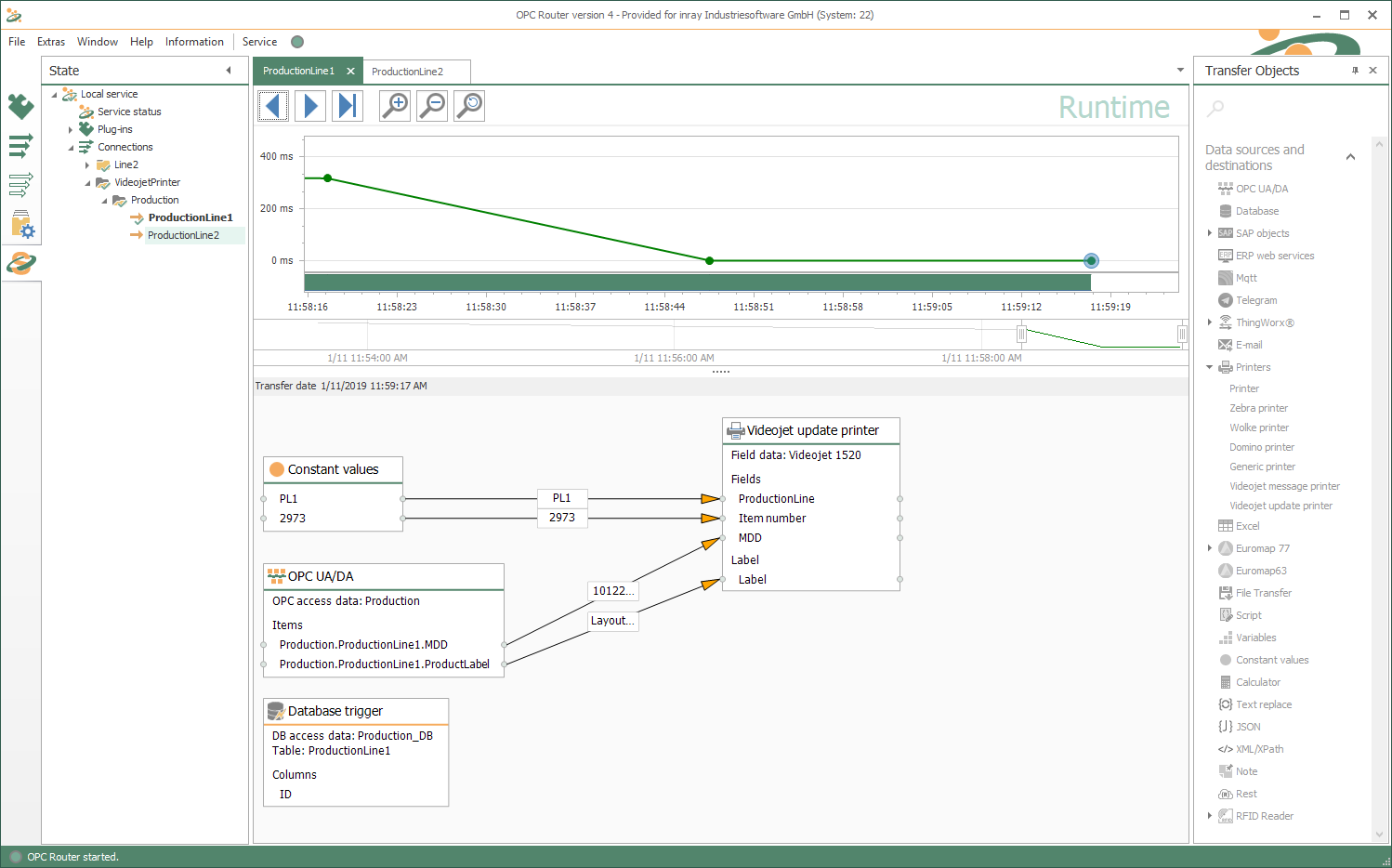

Connecting your systems to a Videojet printer is very easy and intuitive with the OPC Router using drag & drop. This screenshot shows you an example of an application of the OPC Router and the Videojet printer. OPC UA data comes from the machine, which is transferred to the Videojet printer together with the name of the production line and the article number and then printed out.

Bringing Industry 4.0 to life with Videojet

- Achieving more with coupled systems:

With the connection of Videojet inkjet printers via the OPC Router, setting up the printer with print data and layout templates becomes an automatic process, saving time and money. Increasing the number of variants is therefore no longer a problem for labeling process. - Industry 4.0 with Videojet:

Connecting a Videojet printer and automated data exchange integrates the printer into Industry 4.0. The printer becomes part of the self-controlling and self-optimizing production, since it is automatically supplied with the correct print data for production. - About OPC Router:

The OPC Router helps you to connect your systems as data hub. Numerous Plug-ins are available, which qualify the OPC Router as the ideal middleware in industrial settings.

Videojet Inkjet Plug-in application examples

Send job data to the Videojet printer

Identification data for products must be defined in coders for each production order with associated packaging of goods. Different parameters on the label change depending on the customer and article. In modern productions data is already available in databases (e.g. in the MES system). Transfers to the printer is often still done manually at the printer or elaborately via extra software. With the OPC Router print data for layout fields can be transferred directly from the source system to the printer. The selection of the correct data is done, for example, by the unique job number and the line. The data is transferred directly and automatically to the printer at the event of job start, triggered by the higher-level system (e.g. SQL Server) or the PLC (via OPC UA). The automatic setup saves a lot of time and avoids errors in the print data.

Short ways: From SAP system directly to Videojet printer

Using the SAP Plug-in of the OPC router, print data for the printer can also be received directly from the SAP system. For example, you can use a RFC call to retrieve data for a specific request. The SAP system can specify data for individual fields of the layout (including the layout number) or even the entire layout including all data. In this case the SAP system has full control over the layout and layout changes can be made in the SAP system and then sent directly to the printers during the next production run.

Connecting Systems

Transfer-Objects

Two transfer objects of the Videojet Inkjet Plug-in are available. One allows access to layout fields and selection of the currently used layout. The second transfer object allows the transfer of a complete layout to the printer including all print data.

Print data transfer

The layouts stored in the Videojet Inkjet Plug-in only need to be supplied with current data for layout fields for printing. The object for transferring field data transmits the data to the printer fields. The transfer object can also determine the current layout used by the printer. For example, it is possible to transfer the field data from a production order and set it automatically, as well as the used layout, if necessary customer-specific or target market-specific.

Layout Transfer

The transfer object for transferring layouts enables the transfer of a complete layout from an external source to the printer. The transferred layout is set as the current layout and is valid until a new layout is received or a stored layout is activated. This type of layout transfer can be used to transfer layout management from the printer to an external system, especially when there is a large number of variants and frequent layout updates. The distribution of changed layouts to distributed printers is not longer necessary. Layout change requests are implemented in external systems (e.g. ERP or MES) and are applied to the next job after approval.

Trigger

The Videojet plug-in does not have its own triggers. Connections are started by triggers of other plug-ins. For example, the plug-in sends print data to the printer when a signal is sent from PLC or new data is available in the database. All triggers of the other plug-ins can be used together with the Videojet Inkjet Plug-in.

Browsing

If layouts are addressed in the Videojet printer, the field name of the layouts must be announced in advance. The field name from these lists can be searched and selected in the connections.