The SAP system is one of the world’s leading ERP systems and a key tool for industrial applications. There, an SAP system often ensures smooth operations. Various SAP modules also cover different application areas in the production environment. To fully exploit the advantages of SAP systems, there are some challenges to overcome in practice. In this article, we take a detailed look at these challenges and present suitable solutions.

Contents

1. Added value of the SAP connection

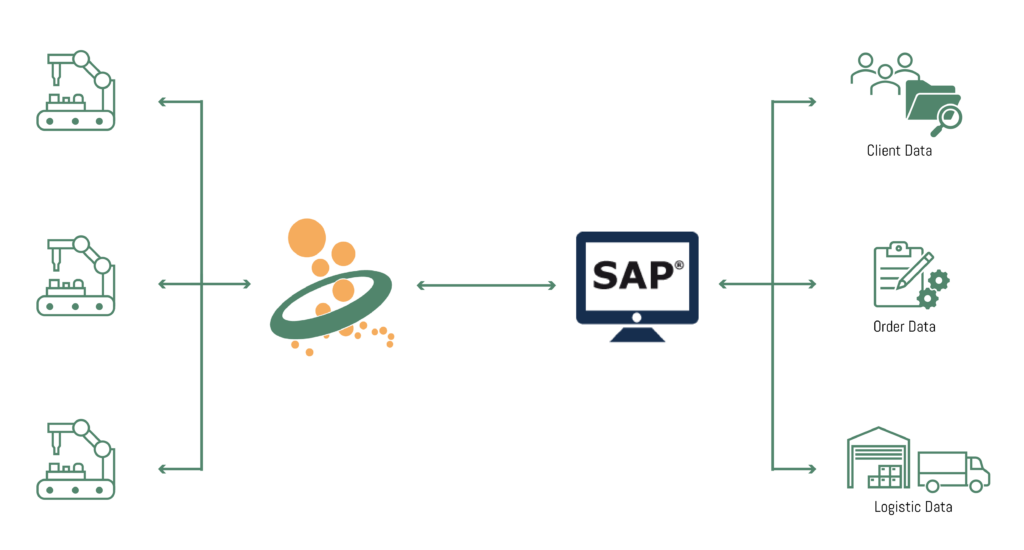

By connecting an ERP system such as SAP, it becomes possible to map all business processes within a company. That has the advantage that the OT and IT levels, i.e. the operational and business worlds, converge. In addition, all resources available in the company are managed. However, a detailed view of specific processes is often difficult under SAP, which in practice often requires the use of additional third-party software solutions.

2. Challenges

Digitalization

In the context of digitalization, there is dynamic competition with constantly increasing requirements. To remain competitive in this environment, the functional scope of the SAP ERP system is often insufficient, as it is only focused on the business and does not consider the operational requirements of the field level (OT).

Heterogeneous system landscape

The industrial system landscape has grown considerably over the years and has become increasingly heterogeneous, resulting in greater complexity and an enormous support effort. The consequence is that it is challenging to integrate SAP ERP into existing operations (OT) systems, which ultimately drives a Smart Manufacturing initiative.

Individualization

The changeover to individualized products, especially in the manufacturing industry, involves a great amount of effort for production planning, set-up times and controlling. Complexity is not only involved in the changeover to the production of individualized products, but also in general changes at short notice, such as changes to the delivery date or the order quantity. Particularly in the case of changes to the general conditions after the production order has been released, cumbersome processes arise.

Central point of contact

Due to the increasing heterogeneous system landscape already mentioned, there is often a lack of a central point where all valuable information converges. Inventory, machine performance, consumption and quality data, for example, must be taken from the individual systems. Collecting the information in this way results in a great deal of work for companies as well as a high susceptibility to errors, which can lead to a lack of an overall view of important production data.

IIoT capability

Digitalization enables costs to be saved by networking and automating production. The SAP system in the production environment offers various options for automating store floor data collection. However, it has not yet been possible to consolidate the data from different store floor systems and use it interactively. That leads to a lack of IIoT capability at the store floor level.

Standard MES function

SAP is an ERP system and therefore suited for resource planning. However, when it comes to detailed order planning, there is no in-house solution from SAP. So, there is a lack of capable standard MES functions. As a result, it is impossible to receive notifications such as error messages from production and operation systems without the use of third-party software. Flexibility, traceability, and transparency in manufacturing are essential due to advancing digitalization, increasing competitive pressure, growing demands on production and the increasing importance of Industry 4.0 and/or smart manufacturing initiatives.

3. Typical use cases in production

SAP application in the production process via RFC

In the production process, automation devices must take over the steering of the production process at many points. Examples of criteria for this are releases, quality, storage capacities, line utilization, etc. For making these control decisions, the respective automation device must request the information from the system that possesses all the data, and often this is the SAP system. On the OT/production side, the use of OPC standards for data interchange between software applications and even hardware is generally accepted, and most OT systems have an OPC interface available. By using a third-party software solution that provides an OPC client and SAP connectivity, it is possible to connect the production data from your OPC Server to SAP. For example, a PLC can use this to trigger a synchronous RFC function call in SAP, transfer the input values and receive the instruction for the next step in the process as a return value. The execution as a synchronous RFC call is important for the production process since the result is immediately available allowing the next process step to be executed.

SAP application in production confirmation via IDoc

A lot of data accumulates in production that is required in the SAP system to carry out production planning. Production messages include data on finished goods, raw material, packaging and auxiliary material consumption or machine running times and statuses. The data can be used to plan raw material procurement, update inventories and schedule machine maintenance. Sending data automatically from the machine to the SAP system saves time, avoids manual data entry, and ensures more accurate and up-to-date data. Rather than a synchronous transfer via the RFC function, such messages could be sent to SAP as an IDoc. An IDoc is a message packet that is processed asynchronously. The production process is consequently not dependent on the processing of the data and can keep moving, while the IDoc handling process assures SAP receives the data because in SAP, the IDocs are then buffered in a queue and processed.

4. The complexity of sole connection

The machines from production frequently unable to communicate directly with the SAP system. That is because there are no general protocols for communication. More concretely, the machines and the SAP system do not speak the same language, such as OPC, which is widely used in production.

SAP is a large and powerful, yet complex application designed to address business and ERP requirements across many industries. However, customizing it to meet individual and unique customer requirements is a significant challenge. As with any enterprise-scale application, this requires an ecosystem of third-party vendors. That can lead to complex processes when customizing to specific requirements. That always depends on whether the third-party solutions have the right focus on leveraging SAP-certified connections and solving problems without creating further problems through unnecessary complexity.

5. Frequently used interfaces for SAP connection

The SAP standard interfaces offer many possibilities to connect external systems to SAP and to exchange data. The following SAP interfaces are available:

6. SAP PCo (Plant Connectivity)

With SAP PCo, SAP offers a software component that enables data exchange between an SAP system and industry-specific standard data sources from different manufacturers, such as process control systems, plant historian systems, and SPC systems.

Using PCo, data points (tags) and events can be received automatically or on request from the connected source systems in production and these can be passed on to the connected SAP systems. PCo also allows to issue, receive and process OPC UA Method calls to map complex coordination tasks in the machine control (PLC) environment. Note that not all OPC UA servers or clients support UA Methods and it is different than plain OPC UA. The PCo Web Server extends these possibilities and allows the provision of self-defined methods in the form of web service operations.

7. The OPC Router with the SAP Plug-in

The OPC Router is a software solution that networks your machines and systems. SAP systems can also be easily connected to the OPC Router. Through connectivity between plants, devices and systems, workflows can be automated and processes optimized. This intelligent networking of processes and machines provides the basis for Industry 4.0. The OPC Router is a classic middleware and can be integrated into existing automation and production environments easily, quickly and without expert knowledge or programming skills.

The OPC Router allows the connection of all available SAP systems, which results in a wide range of applications. The connection to the OPC Router enables the transfer of production-relevant data up to the PLC or other networked devices in production. Processes are automated, reducing manual intervention to a minimum. That leads not only to an acceleration of business and production processes, but also to the avoidance of errors. The OPC Router is capable of handling all SAP interfaces that have already been pointed out (RFC, BAPI, IDoc, REST, SOAP and SAP HANA). System integration with the OPC Router also requires little effort, resulting in scalable projects. Migrating new interfaces such as SAP HANA is easily implemented without a plentiful time investment.

8. Comparison of SAP PCo and OPC Router

Due to its connectivity, OPC Router is able to connect significantly more systems than the in-house solution SAP PCo, which results in higher scalability and performance. Especially with more complex systems, the workflows can only be displayed to a limited extent with SAP PCo, whereas OPC Router is able to display them correctly. In addition, the OPC Router can adapt to SAP processes through its flexibility in order to achieve transparent communication in production.

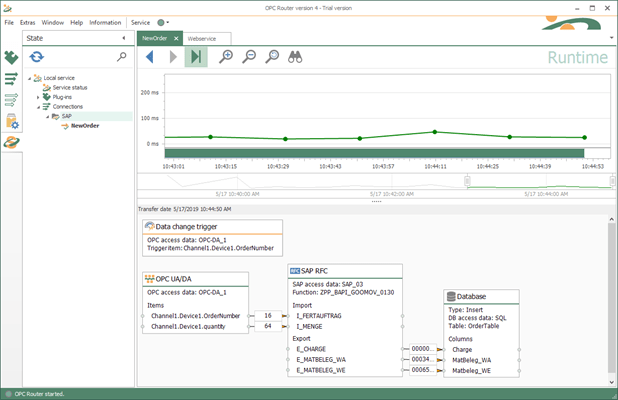

9. Implementation of SAP in the OPC Router

Within the OPC Router are two systems for the data transfer stored: Source and target system. One of these is the SAP system and, for example, an OPC UA server as an additional system. The OPC Router works with a graphical user interface. After configuring the two systems, the corresponding objects can be selected and transferred to the interface by drag & drop. These objects can then define with the systems configured at the beginning. In addition, special settings and configuration of the parameters must be made. When this is done, the individual objects can relate to graphical arrows. The connection can then be activated and monitored in live monitoring. No programming knowledge is required for this process. You can find our video tutorial on this for a detailed description.

The screenshot shows the graphical user interface of the OPC Router with an established SAP connection. You can see how order numbers and quantities are written from an OPC data source to the corresponding SAP variables. Subsequently, information about the batch, goods issue (raw material) and goods receipt (finished products) are forwarded from SAP to a database. The trigger for starting the data transfer is defined as the change in the order number.

Further information

Do you want to learn more about the individual standard interfaces of SAP? For this purpose, we have provided you with everything on this topic on our page. Here you can read all the details.

With the OPC Router Plug-in for SAP systems, you can easily and efficiently couple them with your system environment. That allows you to make data transfers between SAP and machines transparent. See how this Plug-in can advance your Industry 4.0 project.

Want to learn more about the OPC Router? Check out our detailed page about all the details of the OPC Router and how it can help your project.

Further interesting articles on the topics of Industry 4.0, cloud, technology, alerting and practical application examples as well as case studies are available in our Knowledge Base.