Domino Coding & Labelling Systems

Easy data supply for Domino printers

Domino is one of the leading identification technology manufacturers, which is used across various industries. The OPC Router is able to connect all printer of following series: A-Series, A-Series+, Ax-Series, M-Series, as well as printers with the CODENET protocol.

The connection to the many different plug-ins of the OPC Router is done graphically by Drag&Drop. Label printing can thus be supplied with data from various systems and existing media breaks can be eliminated. The electronic transmission of the correct print data at the right time saves time by avoiding manual activities and money by avoiding wrongly labelled goods due to input errors.

See in our tutorial video how easy label printing is with our plug-in for Domino coding and labelling systems or find a detailed video on this topic, using the Windows printer as an example, under the description “connecting different printers” here in our tutorial stream.

That’s how easy it is.

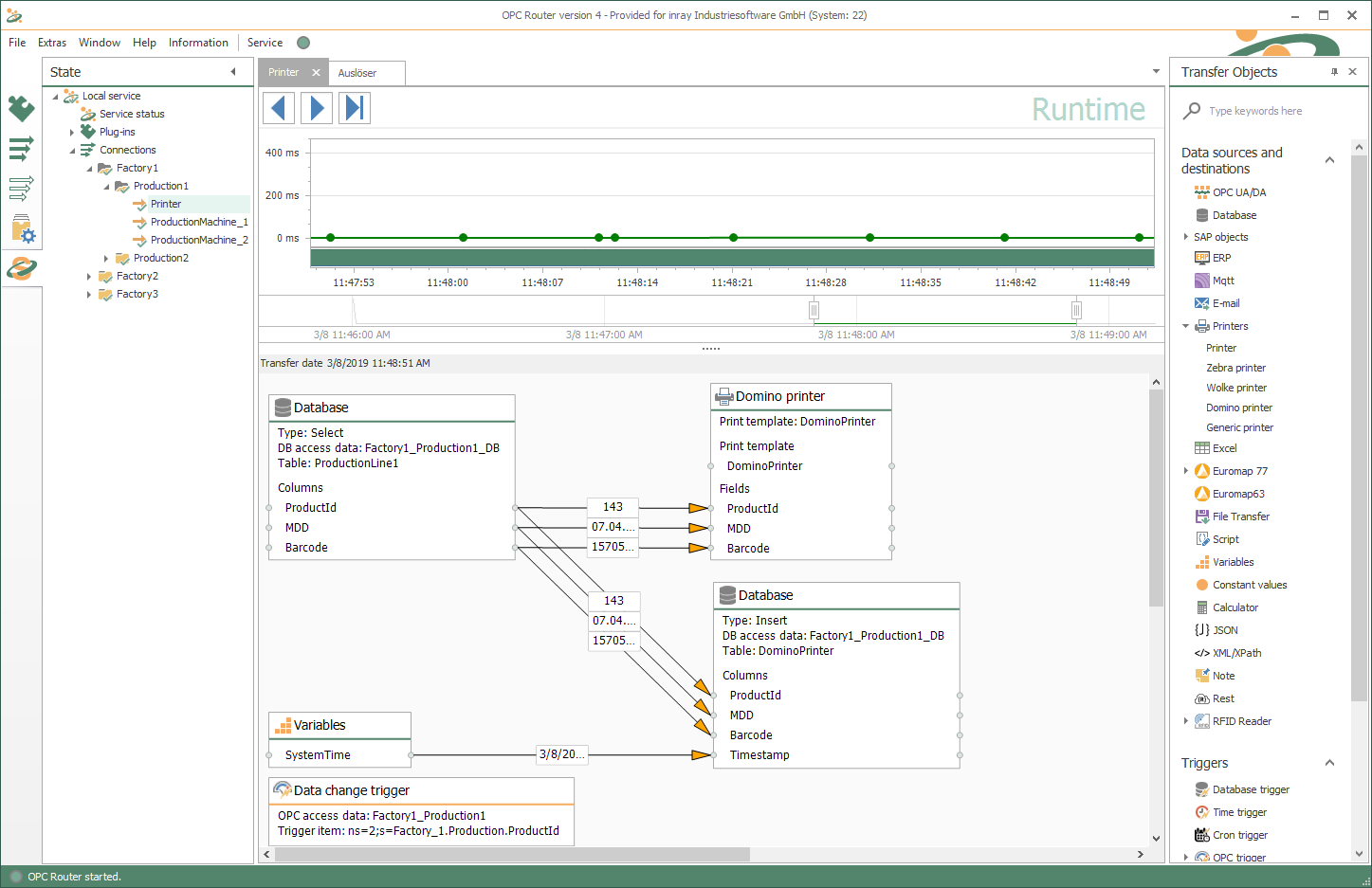

Domino Printer connection via drag & drop

Connecting your systems to a Domino Printer is very simple and intuitive with the OPC Router via drag & drop. This screenshot shows you an example of an application of the OPC Router and the Domino Printer. The OPC Router receives data from an SQL database and automatically forwards it to the Domino Printer. At the same time, the data record in the SQL database is updated together with a time stamp.

Bringing Industry 4.0 to life with Domino Printer

- Achieving more with coupled systems:

Printing systems are very important for product labeling. Wrong or missing labels can result in sizeable economic damage. Using the printer in combination with the data transmission capabilities of the OPC Router will help prevent huge time losses and costs due to human error. - Industry 4.0 with Domino:

Manual configuration is a thing of the past, since the OPC Router and the Domino Plug-in links your Domino printer into the Industry 4.0 infrastructure. - About OPC Router:

The OPC Router offers a visual network configuration interface for successful cross-linking of your systems. A high variety of Plug-ins turn the OPC Router into a powerful data hub for industrial applications.Easy configuration, sophisticated monitoring and robustness are main distinguishing features of the OPC Router.

Domino Label Printer application examples

Set up EXP date printing automatically

The printed EXP (expiration date) on a product with a limited shelf life is decisive for its saleability. A product with an incorrect EXP will result in complaints or will be directly declared as scrap. The correct setup of the printer with the EXP of the production order is therefore an important step when starting the production order. A manual execution of the setup process bears a high risk of wrong entries and operating errors. With the OPC Router plug-in for Domino printers, the EXP specifications can be automatically sent to the printer during the setup phase of the production order. The data is retrieved from the order data of the started job from a database or directly from the MES (SQL Server) or ERP (e.g. SAP, SOAP, REST) and then transferred. The result is the best possible protection against wrongly marked products.

Identification data from the controller to the product

If the layout of the product labelling contains batch numbers or sequential numbers from the PLC, the data must be transferred to the printer during the running process so the marking is synchronous with the product being manufactured. Especially in case of transport routes with different sources and identification data carried by PLC, print data is determined dynamically during the process. With the OPC UA interface (OPC Client Plug-in), data can be retrieved in the same way from different field devices and then directly incorporated into the labeler’s print job via Domino plug-in. This makes it easy to set up production processes that adapt dynamically to the process.

Video: That’ s how easy it is to print with the Domino Printer Plug-in

In our tutorial video we show you how easy it is to set up a print job for Domino printers with the OPC Router in just a few steps. You will also learn how to query the printer status.

Connecting Systems

Transfer-Objects

The transfer object of the Domino Plug-in contains the printing commands.

Fields

The configured template contains comand sequences, and can be enhanced with dynamic fields. The fields need to be created in compliance with the layout. During transfer, the respective fields are filled with the transferred values. Upon completion, the resulting command sequence is sent to the printer.

Status

The status of the printer can be queried via a further transfer object. Valuable information about the operating status, label supply, ink level, etc. can be received, forwarded and evaluated.

Trigger

The Domino Plug-in does not have trigger functions of its own but uses the standard trigger functions of the OPC Router.

Browsing

The Domino Plug-in extracts the filled-in dynamic parameters from inside the command sequence and makes them available for selection.