How does IT/OT integration work?

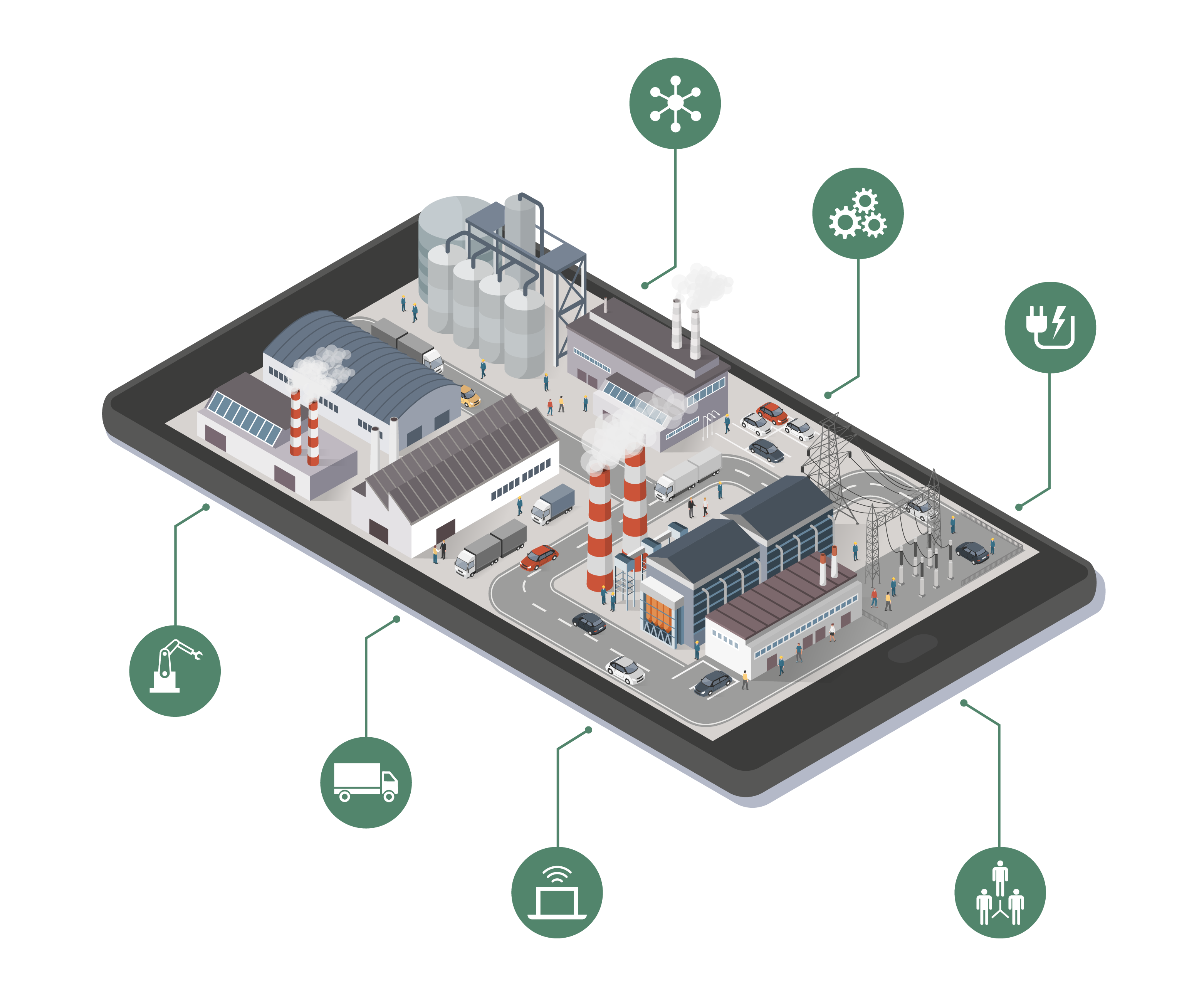

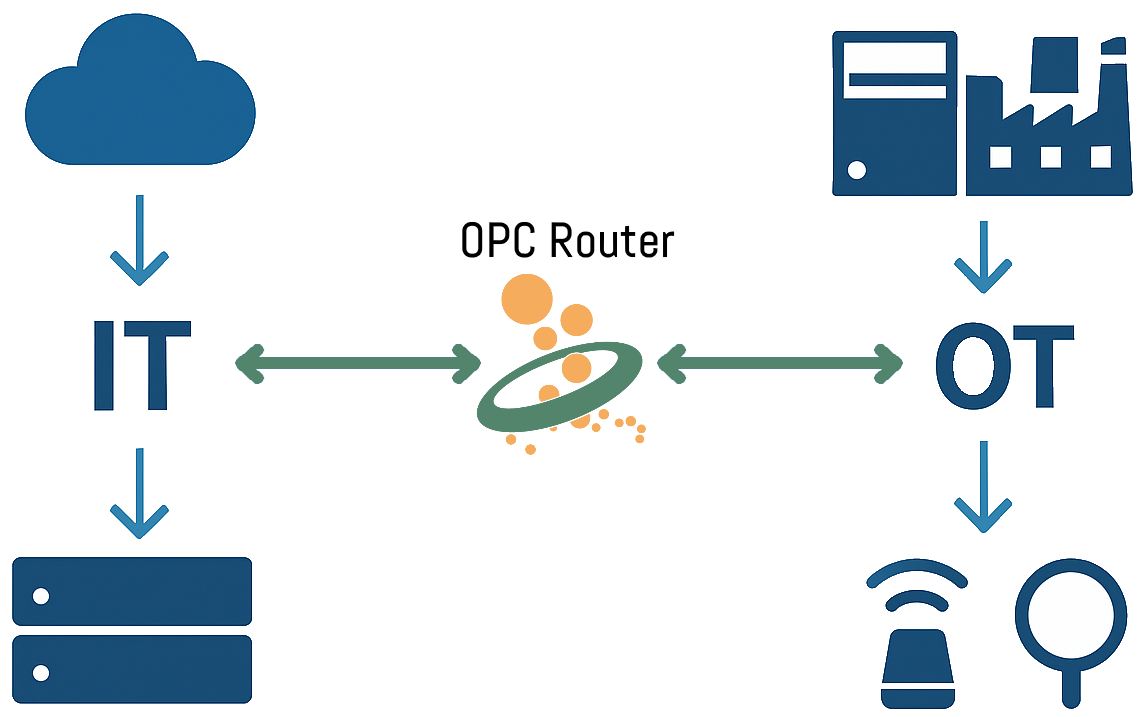

IT/OT integration describes the connection of Information Technology (IT), such as ERP systems, MES, databases, or cloud platforms, with Operational Technology (OT) in production. OT includes machines, PLC controllers, sensors, SCADA systems, and other automation components.

Table of contents

How does IT/OT integration work?

IT/OT integration describes the connection of Information Technology (IT), such as ERP systems, MES, databases, or cloud platforms, with Operational Technology (OT) in production. OT includes machines, PLC controllers, sensors, SCADA systems, and other automation components.

Table of contents

1. What is the goal of IT/OT-Integration?

The goal is clear: Production data should be made accessible in real-time. Only this way can analyses be performed, processes optimized, quality assured, predictive maintenance carried out, or even artificial intelligence utilized in industry. With advancing digitalization and Industry 4.0, the importance of IT/OT integration is growing enormously. Only those who can reliably transmit their data to IT systems create the foundation for smart operations.

Why is this so important? Traditionally, IT and OT often work in separate worlds. IT departments handle ERP, CRM, cloud systems and more, focusing on security, flexibility, and data analysis. OT teams, on the other hand, ensure smooth production processes, stable machines and minimal downtime.

That’s the problem: These two areas function with different logics, use different systems, and sometimes even speak different languages. This leads to important data getting stuck in production or only reaching IT in insufficient quality. This creates obstacles for projects like predictive maintenance, business intelligence, or AI-supported production optimization.

This is exactly where IT/OT integration comes in: It builds a bridge between systems, ensures standardized data flows, and creates the foundation for digital added value.

2. The five biggest challenges in IT/OT integration

Here we highlight the challenges and offer solution approaches on how the OPC Router provides support:

2.1 Challenge: Cultural and organizational silos

IT and OT often work in separate teams, with their own goals, processes, and terminology. While IT focuses more on updates, flexibility, and security, OT is focused on stability, availability, and long runtime.

Why is this problematic? When mutual understanding is lacking, integration projects stagnate. IT wants to integrate new systems, but OT may hesitate out of fear of production downtime.

Solution with OPC Router: The OPC Router offers a user-friendly, graphical interface that allows IT and OT employees to create data flows together using drag-and-drop without any programming knowledge. This ensures transparency, understandable collaboration, and quick adjustments.

2.2 Challenge: Technological complexity and heterogeneity

Many factories have machines from several decades. Old controllers meet modern cloud applications, specialized systems meet open standards like OPC UA or MQTT.

Why is this problematic? Each system speaks its own language. Without a central platform, a confusing mix of isolated solutions, gateways, and custom developments emerges. This is expensive, maintenance-intensive, and error-prone.

Solution with OPC Router: With over 50 pre-built connectors (e.g., OPC UA, Siemens, Beckhoff, SAP, SQL, MQTT, REST API…), OPC Router offers a unified platform for integration. Different systems can be connected without programming effort, making production scalable, future-proof, and low-maintenance.

2.3 Challenge: Cybersecurity and risk exposure

Many production systems are not designed to be accessible from the outside. Many controllers have neither authentication nor encryption, making them vulnerable to attacks.

Why is this problematic? When these operating systems (OT systems) are connected to IT networks, potential entry points for hackers or malware are created.

Solution with OPC Router: OPC Router uses encrypted communication, such as MQTT over TLS or HTTPS, and can be integrated into secure network structures like DMZs or zero-trust models. Importantly: There is no direct contact between machine and IT system, but rather a controlled data transfer via a secure intermediate station.

2.4 Challenge: Availability versus flexibility

In production, downtime is expensive. While IT systems are regularly updated and maintained, OT systems often need to run for years without interruption.

Why is this problematic? New integrations must not disrupt or interrupt production for long periods, but at the same time IT demands flexibility.

Solution with OPC Router: The OPC Router works on-site or as a containerized solution resource-efficiently and reliably in the background. Updates and adjustments can be performed without affecting ongoing operations. Existing processes remain intact.

2.5 Challenge: Data integration and data quality

OT data is often unprocessed, unstructured, or incomplete. However, IT systems like ERP, MES, or business intelligence tools require structured and meaningful data.

Why is this problematic? Without proper processing, faulty or incomplete data ends up in IT systems, leading to incorrect analyses or inefficient processes.

Solution with OPC Router: OPC Router offers integrated rules, triggers, and functions for data transformation. Data is preconfigured, enriched, and transmitted to IT in structured form. This is ideal for ERP systems, databases, or cloud analytics.

3. Conclusion: The clear strategy for IT and OT

Conclusion: The connection between IT and OT requires a clear strategy, suitable technology, and the right tool. Digitalization in industry is based on well-coordinated IT/OT integration. Without it, terms like Smart Factory, Predictive Maintenance, or Artificial Intelligence remain just buzzwords. But the path is not always easy. Different systems, security issues, and organizational hurdles can delay projects.

Here, OPC Router offers a proven solution:

- Central middleware for IT and OT systems

- Over 50 connectors, from OPC UA to SAP

- Secure, encrypted communication

- No programming effort thanks to no-code approach

- Scalable platform for companies of any size

With OPC Router, IT/OT projects can be implemented more easily, securely, and quickly, and companies receive a reliable data foundation for all future endeavors. Curious to learn more?

4. Micro-FAQ on “What is IT/OT integration?”

- What does IT/OT integration mean specifically?

IT/OT integration connects IT systems (ERP, MES, cloud) with OT systems (machines, PLCs, sensors) to make production data usable in real-time.

- Why is IT/OT integration so important for Industry 4.0?

Without IT/OT integration, data remains isolated in production. It is the foundation for Smart Factory, Predictive Maintenance, and the use of AI in manufacturing.

- What challenges exist in IT/OT integration?

Cultural silos, different interfaces, cybersecurity risks, availability requirements, and unstructured data are among the biggest stumbling blocks.

- How does the OPC Router support IT/OT integration?

The OPC Router offers over 50 connectors, a no-code interface, and secure data connections to connect IT and OT systems easily and scalably.

- Is IT/OT integration only relevant for large companies?

No, because medium-sized companies also benefit from more efficient processes, better data utilization, and lower integration costs.

Which questions do you have about IT/OT integration?

More information

Read what middleware is and how it can help your company. In our “What is middleware?” article, you’ll learn everything about functionality, benefits, and practical applications.

Learn more about machine data acquisition and how it can contribute to optimizing your company. In our article about machine data acquisition, you’ll learn everything important.

With OPC UA, standardized access to machines, devices, and other systems in Industry 4.0 is enabled, ensuring manufacturer-independent data exchange. In our knowledge base, you’ll find an overview of the functionality and terminology of the most important communication protocol for Industry 4.0 and the Industrial Internet of Things (IIoT).

Find more interesting articles on Industry 4.0, cloud, technology, alarming, and practical application examples as well as case studies in our knowledge base.