Wolke Inkjet Printers

Wolke Thermal InkJet Printer Connection

Wolke printing systems print with ink and at very high resolutions. Printing products are used in industrial applications for product labeling. The printers are integrated into industrial plans and can be addressed from inside the company’s network architecture. The printing setup allows various layouts that can be called upon before printing. Besides the possibility of manual data entry into pre-configured fields, it is also possible to retrieve data via OPC Router through the available network connection. You can find a detailed video on this topic, using the Windows printer as an example, under the description “connecting different printers” here in our tutorial stream.

That’s how easy it is.

Wolke Inkjet connection via drag & drop

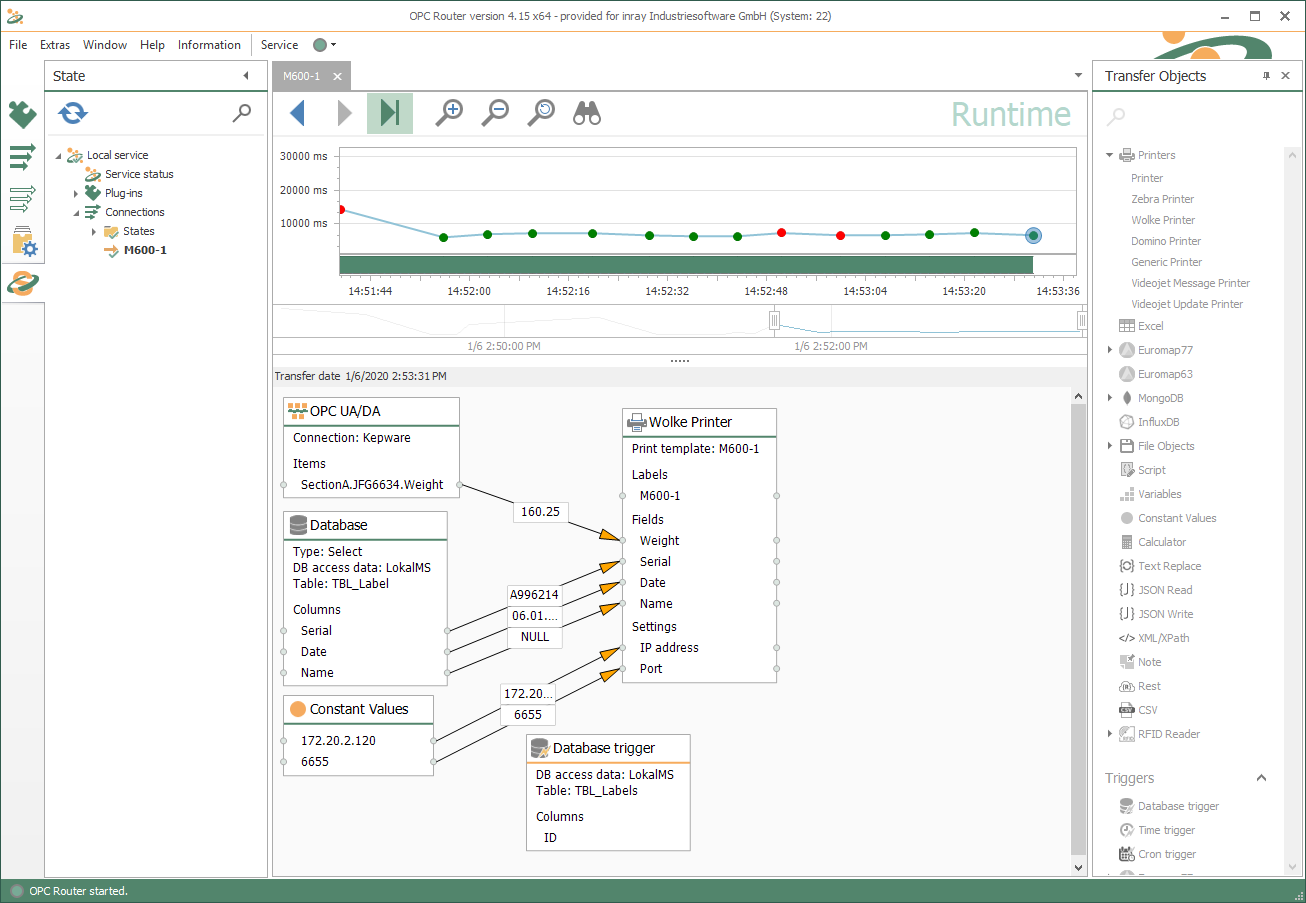

Connecting your systems to a Wolke Inkjet printer is very simple and intuitive with the OPC Router using drag & drop. This screenshot shows you an example of an application of the OPC Router and the Wolke Inkjet printer. A data set triggers a transfer with the database trigger. Then data is read from the database, transferred to a printer transfer object and assembled into a label. In addition to the database data, data is read from OPC servers and transferred to the printer transfer object.

Bringing Industry 4.0 to life with Wolke Inkjet Printer

- Achieving more with coupled systems:

Printing systems take on important product labeling tasks. Wrong or missing labels can result in sizeable economic damages. When a printers is connected with the OPC Router, data exchange can take place coherently, which rules out human errors by tapping into the data source immediately. - Industry 4.0 with Wolke Printers:

Manual configuration is a thing of the past if the OPC Router and the Wolke printer Plug-in work together inside an industry 4.0-enabled infrastructure. - About OPC Router:

The OPC Router offers a visual network configuration interface for successful cross-linking of your systems. A high variety of Plug-ins turn the OPC Router into a powerful data hub for industrial applications.Easy configuration, sophisticated monitoring and robustness are main distinguishing features of the OPC Router.

Wolke Printer Plug-in application examples

Product identification in fully automated process control

In fully automated process control, manual set-up for product marking is impossible and also unnecessary. The data for production are available electronically in SQL databases. With the OPC Router Plug-in for Wolke printers, this marking data can be automatically sent to the printer. The labeling devices from Wolke, such as the Wolke m610, provide interfaces for this. The SQL database is connected as the source via the SQL Server Plug-in. All data can be transferred automatically via this connection when starting and changing jobs.

Product labeling with data from OPC UA

The source of the labeling data that is passed to the Wolke printer with the Wolke Plug-in is flexible. All Plug-ins available in the OPC Router can be used and linked in one connection. With the OPC UA Client Plug-in, for example, data can be obtained directly from controllers. This means that the labeler can be supplied with data for product labeling from the PLC while the process is running, according to the current production data. This allows traceability data such as source lines, batch numbers or machine numbers to be applied to the product.

Connecting Systems

Transfer-Objects

The transfer object of the Wolke Plug-in contains information about layout and fields used for printing.

Layout

The layout determines the respective format and print design, which is referenced by a unique name in the printer’s interface. In the transfer object the respective layout name is the reference point for further action. The respective selected layout can be pre-configured in the transfer. It can also be dynamically determined, which enables processing of printing tasks for various layouts per production job without increasing configuration efforts or configuration time spans, as manual configuration is rendered obsolete, if configuration is Industry 4.0-enabled.

Fields

Each and every layout contains clearly identifiable fields. These fields are registered in the transfer object, and thus become available as data fields for respective transfer configurations.

Trigger

The Wolke Plug-in does not have trigger functions of its own but uses the standard trigger functions the OPC Router offers.

Browsing

The Wolke Plug-in presents pre-configuted fields as data fields. Additionally, information is provided about the label name, IP address, and printing port, which are also generated as data fields.